- EV Tech Insider

- Posts

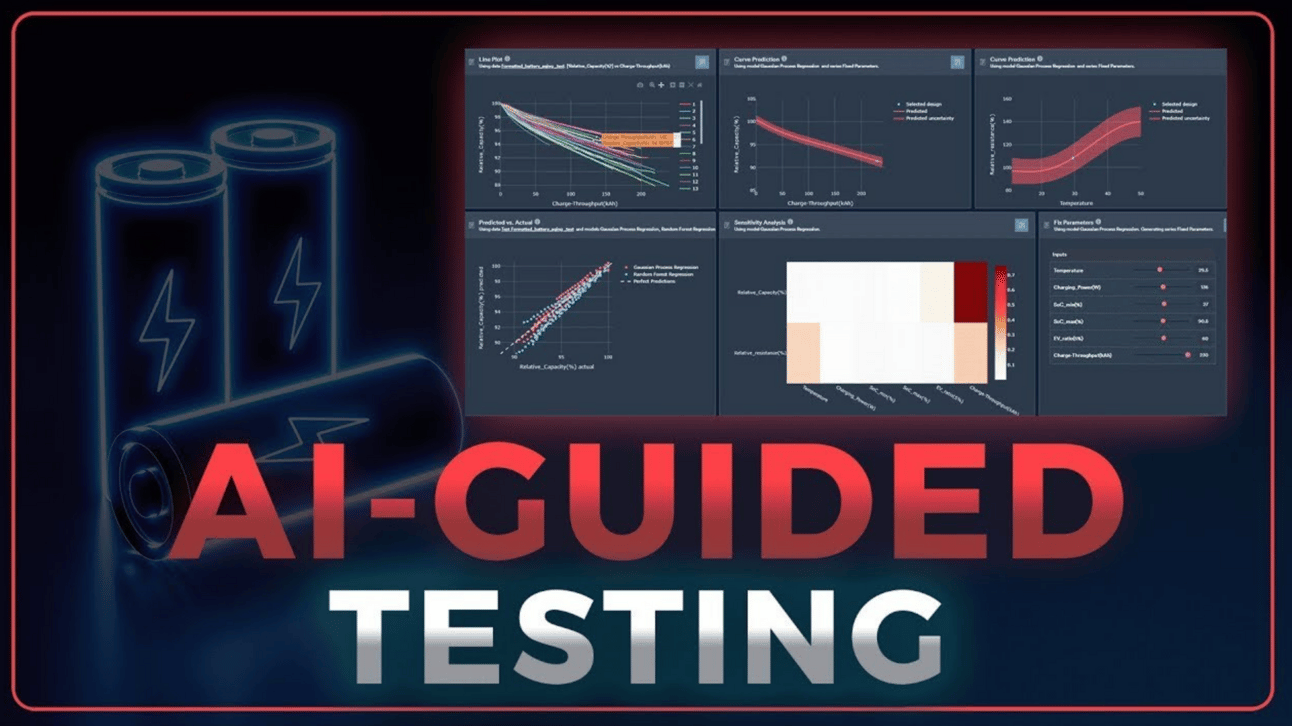

- How AI can reduce battery testing time by 50-80%: Monolith AI

How AI can reduce battery testing time by 50-80%: Monolith AI

With AI-guided tests, engineers can navigate the intricate challenges of battery validation more efficiently to get new products to market much faster.

What is Monolith AI?

Monolith is an AI-guided testing tool that allows manufacturers to build AI models from test data so they can understand how the design works, make predictions, and optimize the design.

Monolith adds value for engineers of complex, nonlinear designs that are difficult to fully simulate characteristics such as wind turbulence, electrochemical reactions, mechanical systems and how they react to different forces, and so on. For simplicity, just about any product that you will ultimately drive, float, or fly may have these types of challenges. These challenges require a heavier investment in physical testing to develop and test new designs. With AI machine-learning models, you can better understand how the design will perform and as a result, create more efficient test plans.

Dr. Richard Ahlfeld, our founder, was working on rockets at NASA while getting his Ph.D. He was tasked with simulating the vibration stresses on a rocket as it goes through launch. As you can imagine, that’s a pretty tough challenge.

(Founder – Dr. Richard Ahlfeld)

Traditionally, you do this with math-based simulations of every bolt, joint, surface, etc. In these incredibly complex simulations that can take weeks to run in some cases. Many system or design changes could require weeks of rerunning simulations. It was then that Richard realized he could take test data from a prototype and build a machine-learning model of the rocket for a much simpler approach and more accurate understanding of those forces. That’s where Monolith was born.

From there, Monolith built a platform allowing engineers to leverage test data to build machine-learning models to help you understand how your design operates.

What type of data can engineers use to build the machine-learning model?

Monolith can handle several types of data. Fundamentally, it’s tabular data that includes the inputs and outputs from your test programs, and that tabular data could represent almost anything.

In terms of measurement types, you can make electrical, physical, stress, strain, temperature, really any type of condition or design parameter around operating your product, and measure the outputs that matter the most.

How does the data loading process work, and what happens next?

Monolith is built to support a common data science workflow of loading data, analyzing it to understand its characteristics, transforming the data so that it is appropriate for use in an ML model, and then creating models for predictions and optimizations. In the initial step, you simply select data files to load, similar to many tools you are familiar with. Using the Explore functions, you perform simple analysis on the data or visualize it to learn more about it, such as:

How many rows and columns do I have?

What data types are in my data?

What are the column headings?

What are the most common values?

Do I have any gaps or repeating values?

Does my data exhibit any anomalies or discontinuities?

These initial analytics enhance your understanding of your data.

Next, Monolith has several tools to clean and transform this data. For example, you may have different waveforms that were acquired at different time sampling rates. With Monolith, you can realign things to be at the same sampling rates. Or you might need to extract specific features or statistics from your data for use in modeling, such as the amplitude, range, RMS value, averages, filters, or derivatives. The tools help you identify and fill in gaps before you begin working with it.

After the data is prepared, you use it to train a model. Once you have a model, you can create predictions for how the design will perform at different input conditions. For example, when developing a new EV battery, you have to balance multiple parameters to get the optimum lifetime of the battery. If you charge the battery using a very high current or charging power, the consumer will be happy because the battery recharges very quickly. However, over the long run, this approach will significantly reduce the long-term lifetime of the battery. The flip side is you can recharge very slowly to get a longer lifetime, but consumers will be annoyed that the battery takes too long to recharge. When you combine 8 or 10 other factors into the equation, such as how high you charge the battery(100% capacity? 90% capacity?), how low you discharge the battery, different operating temperatures, how quickly you discharge the battery based on driving behavior, and so on – it gets very difficult to make these tradeoffs in the human mind.

AI models are designed to handle this level of complexity. With a model in place, you can predict how the battery will behave under different conditions, enabling you to make tradeoffs in your test plans to save time. For example, if you can accurately predict that the battery performance doesn’t vary much between different values of maximum charge, or under different temperature conditions – you don’t have to test for those. You can remove those conditions from your test plan and focus on the parameters or parameter ranges where the biggest unknowns still exist.

One critical point: Similar to Chat GPT, garbage in means garbage out. When you’re talking about engineering and machine learning, it all comes down to your data. Some companies have a mature strategy and understanding of how they organize their data across different generations of products and different product lines. In other companies, the fundamental challenge is they don’t keep their data structured or documented in a way that they can take advantage of it.

Companies are saying, ‘We’ve got gold in our data and we need to prep it so we can use it in modeling so we can use it in AI.’ Now, we don’t necessarily do that preparation for them, but we understand all of the caveats and issues around engineering data required to generate the best models, and we offer training on what are those factors to make your data useful.

The digitization of your enterprise is what allows you to move much more rapidly with something like AI when it comes onto the scene. Those forward-looking companies will be able to leapfrog very quickly.

What are some of the standout features of Monolith resonating with engineers?

One of the best benefits of Monolith is the ability to automate tedious, expensive, and time-consuming engineering work. The bottom line: you reduce the time spent or number of tests needed by upwards of 50-80% depending on the situation.

Using AI to guide your testing and test plan can make your testing much more efficient, allowing engineers to cover much more of the design space in the same time and effort.

One thing we’ve done is develop new algorithms that can be thought of as anomaly detectors. Many prototype test systems are very complex. You can have literally hundreds or even thousands of sensors and signals that you’re acquiring, and there’s a lot of potential for bad data. You can run into sensor failures, wiring issues, or scaling factors that are off. Customers may use a test facility, such as a test track, wind tunnel, etc. where it’s a very high-pressure, expensive experience with the potential for failures in this early data collection phase. With anomaly detection, rather than going back to the lab and then realizing you have issues and returning to the test site, you can run the data you’re acquiring through a model that will help identify channels or signals that may have a problem.

The other big feature that’s relatively new is the next test recommender. Think about how people design their tests today, it’s a set of parameters and a range of those parameters that you have to sweep through to test your design. That may look like sweeping through temperatures in a temperature chamber, voltages, currents, stresses, strains, etc. The challenge is: what is the right combination of those parameters and values that will tell you the most about what you need to know? There are numerous philosophies about how to come up with that test plan. Some engineers employ a full factorial where they’ll test every combination of every parameter, which may feel like it’s complete, but it’s incredibly expensive. With Monolith, once you have a model of your design, we can take initial test data and tell you based on those initial points, here are the next set of conditions or values you should test. The model can identify which parameter values will uncover the greatest unknowns about your design. This creates a more iterative process where you begin with a little data and do a little testing, then you’re guided to the next best test steps to explore the full capabilities of the design that matter most.

Monolith can be applied to several industries, but I’ve seen several webinars about EV battery validation case studies. Is this your biggest target? Why is that?

EV battery validation is our big focus, and it’s received a lot of traction and interest for a few reasons.

The business, technical, and competitive ramifications of electrification in the automotive industry are huge. Batteries tend to be the most expensive component in an EV, and they define the value of the car. Range, charging time, performance, lifetime, etc. all of these pressures are on the battery. In addition, batteries are a very complex technology. The chemistry, electronics, and thermal characteristics interact in a very complex combination that is very difficult to simulate

EV OEMs spend an incredible amount of money, time, and effort on battery testing to understand these issues and find the best profile to maximize their batteries. They spend years testing to enhance the batteries, and AI brings a lot of opportunities to reduce the testing burden while also increasing the coverage of data so you understand how that battery will perform. We’re seeing an incredible amount of interest and excitement around AI as the economic and business challenges are pushing this EV battery challenge forward.

Your whitepaper with Forrester Research, The State of AI and Engineering, mentions AI can solve a few key problems such as inefficient testing exposing manufacturers to financial risks due to product delays, creating an accurate data-driven model after testing a prototype and recalls due to quality issues. Could you walk us through how Monolith helps solve these engineering problems?

The source of all of those challenges can be solved by understanding the performance of your design and resolving design failures much earlier in the validation process. There’s a long-held fantasy that ‘we can simulate everything in software and never really have to test anything, and that will streamline the whole process and tell us everything we need to know.’ For engineering leaders, that’s just not reality, though the dream is worth chasing. The real question is how much testing do we have to do? The more we know about the designs and how they behave, the better we can identify exactly what conditions need to be tested, and nothing more.

Data-driven modeling allows you to understand the behavior of designs that you can’t simulate. This offers another lever to understand the behavior and predict how it’ll perform. As you go further down the engineering workflow, like building prototypes, it becomes very expensive, especially if you have to do multiple complex prototypes. The more rounds you do, the more you accrue engineering challenges, risk, time, and ultimately cost. Our entire focus is to give engineers tools to understand more and test less, giving a better view of design performance across several different conditions.

What does the adoption look like so far?

Like any new technology, there are companies aggressively adopting and trying to get ahead of the game, and others that are more begrudgingly realizing they need to figure this out or fall behind. They come in all shapes and sizes.

Many of the larger companies we work with are investing in data science teams. We encountered companies with an engineering group that really understands the product and how it behaves and a data science team that understands the math. The challenge is bridging the gap, so that engineers can move quickly and apply these new AI aspects to the design challenges they have and pull in the data science experts for the truly unique issues. Monolith is a great platform for providing a translation tool where engineers can apply data science to the engineering process.

Another key capability of Monolith is providing a platform for deploying AI solutions. It’s one thing to build a model or perform analysis in a vacuum. It’s another challenge completely to apply analytics models within a process used by many engineers. With Monolith, engineers can create a dashboard that is a simplified interface that other engineers or teams can use on their designs. It also has an API so you can integrate the models into other tools and processes. For example, when you’re using Monolith to recommend test conditions, you can automate the process of analyzing the test results in Monolith and send recommendations for the next round of testing back to the test system.

In all of these examples, our approach is to empower the engineer to harness AI for their particular project or design decision. Monolith doesn’t require a Ph.D. in data science or advanced programming experience. It’s built in a no-code environment that allows you to very quickly pull your data, understand the state of that data, and then build models and start making predictions. We unlock the engineering department with a tool designed to accelerate the testing process.

Will this tool eliminate jobs?

There’s a lot of talk about whether AI will replace people and whether it is a threat. We should look at AI as very similar to other productivity technologies that revolutionized industries in the past. For example, when the spreadsheet came out 35 years ago, it could have been viewed as a threat to financial analysts. On the contrary, spreadsheets not only made financial analysts much more efficient but also opened financial analysis to the masses. It became an incredible tool to drive efficiency and effectiveness in that space, and AI can do something similar.

People who use it will gain a competitive edge and forge ahead. It’s not about the threat of AI, it’s the threat of falling behind if you’re not taking advantage of AI. It’s a tool to enhance your competitive position. Is it the only factor that will dictate success or failure? No, but as I mentioned with batteries, market forces and competition are so strong, and now the automotive playing field is leveling out with AI. One of the challenges we have is that the battery supply chain is concentrated in China. There are a lot of forces driving investment and development of battery labs in Europe and North America. I think AI can be a tool to quickly ramp up production and gain a competitive advantage.

The AI hype is exploding at the consumer level, and it’s dragging more people to this realization that they have to understand how it can help them to be competitive. There’s a lot of opportunity. Some people are embracing it and getting ahead, and there are plenty of others just waking up and realizing they need to act or fall behind.

Where do you see Monolith in five years?

Wow, 2029. It’s hard to wrap your head around what the future might look like as the technology is developing so quickly. We see a lot of opportunities right now, and our primary focus is design validation. We also want to optimize areas further up the design process and further down into the manufacturing process.

When it’s time to design a new product or a new version of that product, you start with new requirements. Wouldn’t it be great to have a database of existing models that tells you how your full fleet of previously designed products operates under all these different conditions? With that at your fingertips, you can start to design the product at a much more detailed level using AI, because different aspects of the design react to different conditions and different values. We see the benefit of starting in the test and validation area because that’s where the biggest cost, risk, and efficiency opportunities exist. Ultimately, all of these models can feed back into the ideation and product design stage. We see a long, healthy roadmap for AI opportunities in the engineering space.

Reach out to Monolith

Reach out to Monolith

Special thanks to John Pasqaurette for the interview!

The post How AI can reduce battery testing time by 50-80%: Monolith AI first appeared on EV Tech Insider.